Reflecting on manufacturing and where I started

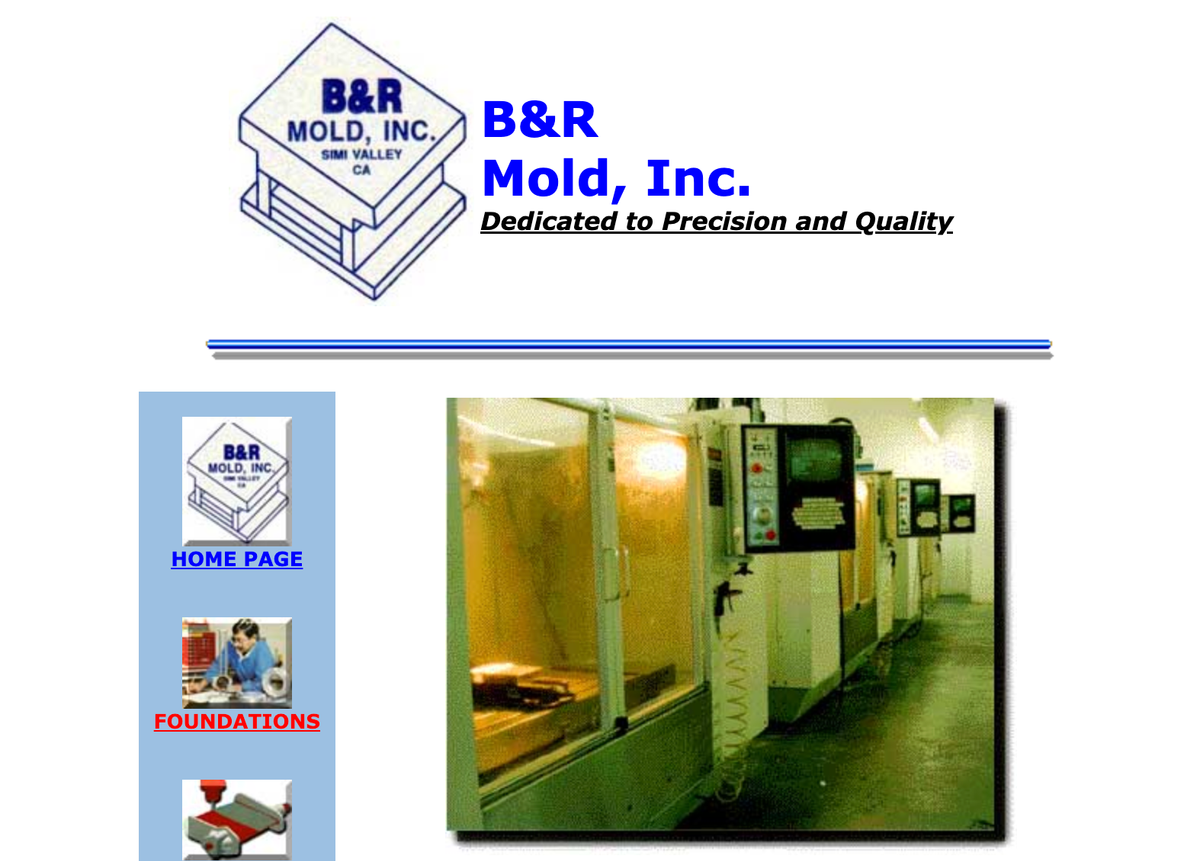

Today I watched a SmarterEveryDay video where Destin talked about trying to manufacture a simple grill scrubber using only materials built made in the United States. It was a fascinating video to watch because he had so much trouble trying to find purely U.S.A. made materials and parts. It also brought back a number of memories when he talked about trying to get a mold made to create his plastic components. You see, I was working in a machine shop making molds when Shannon and I were married. The machine shop in this image was where I worked and it is the beginning of my adult work life.

One of the things that Destin was upset about was that the US is losing so much skill in building tools to make things. He made the point that the US used to make the tools that others operated to make stuff. Now the US buys the tools to make stuff from overseas and operates them. In the machinist world, we are losing our tool and die makers to retirement and death. He gets into why it is so difficult to make a tool, because the skills to be a tool and die maker take years to build. Even in a highly computerized environment, there's a lot of knowledge and experience that goes into designing and building a tool.

I reflected on his video because of my experience in becoming a mold maker (or tool and die maker) when I was in my 20s. I got the job because I had learned computer aided drafting (CAD) and the owner of the shop thought I would do well in the trade. I actually worked in the shop from 1997 to 2001, or a bit over four years. I started out how learning how to make aluminum sheets flat within .001 of an inch. That sounds really simple, but it gets more difficult when you find out that aluminum will flex as material is removed and you risk the sheet being flung off the machine if you took too much off at once! After four years of working in the shop I could build a mold mostly on my own, but there was still a lot I had to learn. I was just getting productive and useful! Four years!

Now that I think about it, I feel kind of bad for leaving the shop. The owner invested a lot into me and I ended up leaving. There were a number of reasons for leaving the shop. First, my wife was expecting a baby, second I wanted to be an engineer, and third I was watching my father-in-law lose his mobility due to Multiple sclerosis. Plus I watched a few injuries and had to get stitches myself. I decided to go into IT instead, due to that baby on the way.

My point is just that it is indeed a problem that the US (or any other country) can't manufacture the things we need. We saw the impact of that during COVID-19 when supply chains were heavily disrupted. It took a long time for things to work out from a supply chain that long. It is sad to see that we are losing the knowledge of how to do things that we used to have. What was once a strength is now something we've lost. Building that back up is a work of decades. There's just no way to flip a switch and turn that back on again.

P.S. On May 6, 1999 I stood in front of the mill in the foreground in the image above absolutely freaking out. My wife had told me the night before that we had a baby on the way and I knew that I had a long way to go to support a family. It's a fun memory now, but at the time I remember being extremely stressed out about it. 😃